Course: Studio with Professor James Malazita (MS, PhD)

Group Members: Alex Brush | Max Parizot | Nampoina Randrianarivelo | Bill Ruan

Project Theme: Designing for local Troy, NY businesses

Local Business Partner: Collectiveffort: A Creative Agency startup that focuses on Community-Centered Marketing, Media Production & Community Development (coworking)

Project Learning Outcomes: Client communications, problem definition, ideation, concept selection, prototyping, 3D modeling/rendering using Rhino 3D and Unreal Engine

Identified Stakeholder Needs |

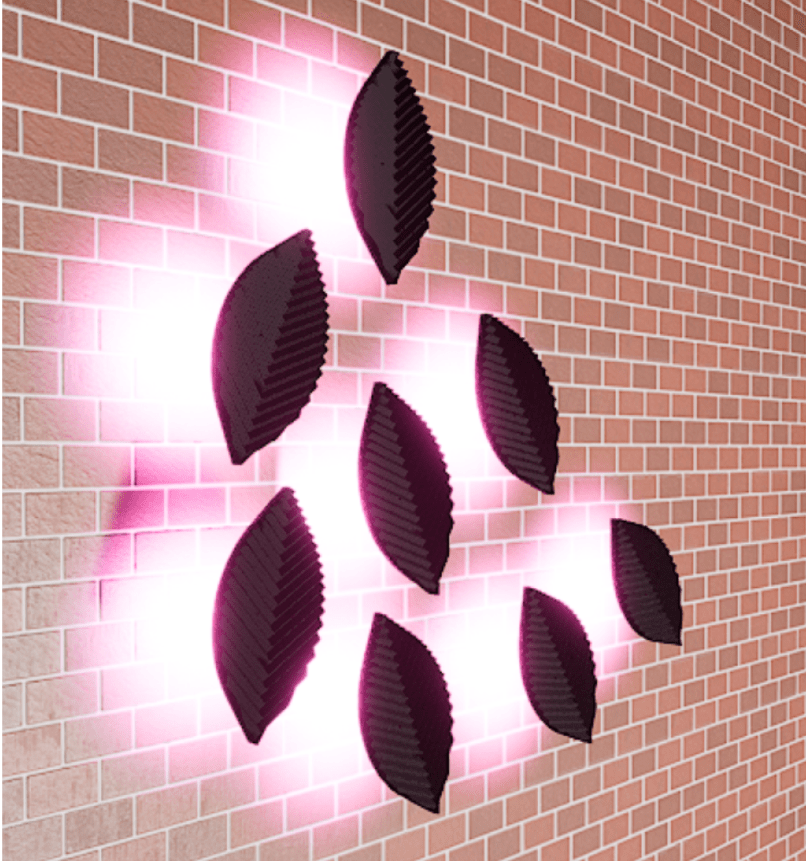

Through initial discussions with our stakeholders, they expressed the need for an acoustic treatment product for their newly renovated creative space. They also mentioned that they want us to include a lighting component to the paneling because they want people passing by to be attracted to the glowing light emanating from the room.

Outcome: Navigated stakeholder communications while in the midst of a global pandemic and the company experiencing rapid business expansion.

Problem Statement |

“How do we design for Collectiveffort’s need for functional and aesthetically pleasing acoustic treatment for their media production studio?“

Ideation & Concept Selection |

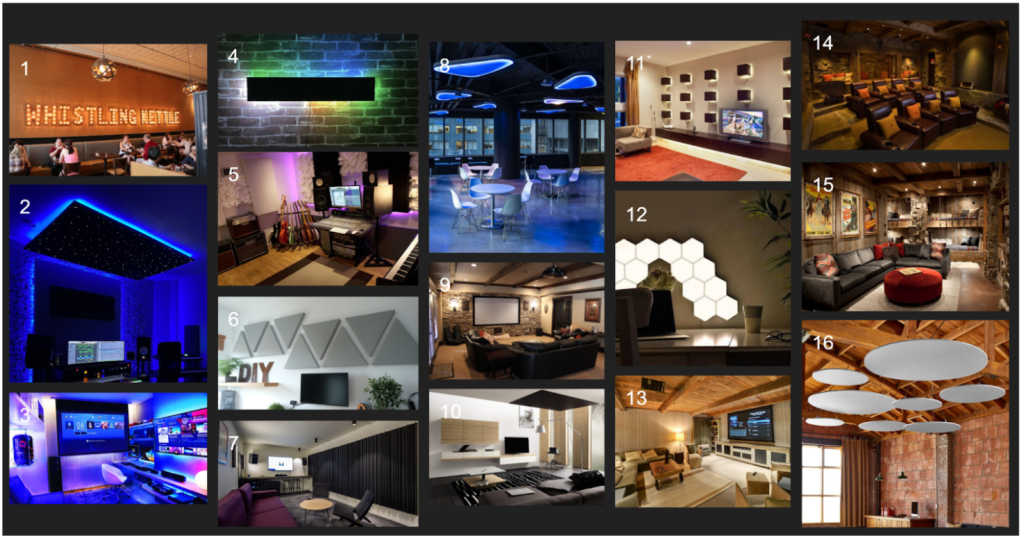

Our moodboard served as the starting point for our design and to help our stakeholders visualize initial product concepts.

Outcome: Received essential moodboard and pin-up feedback from stakeholders that they like the ambient lighting, leaf-shaped panel, and hexagonal acoustic pattern.

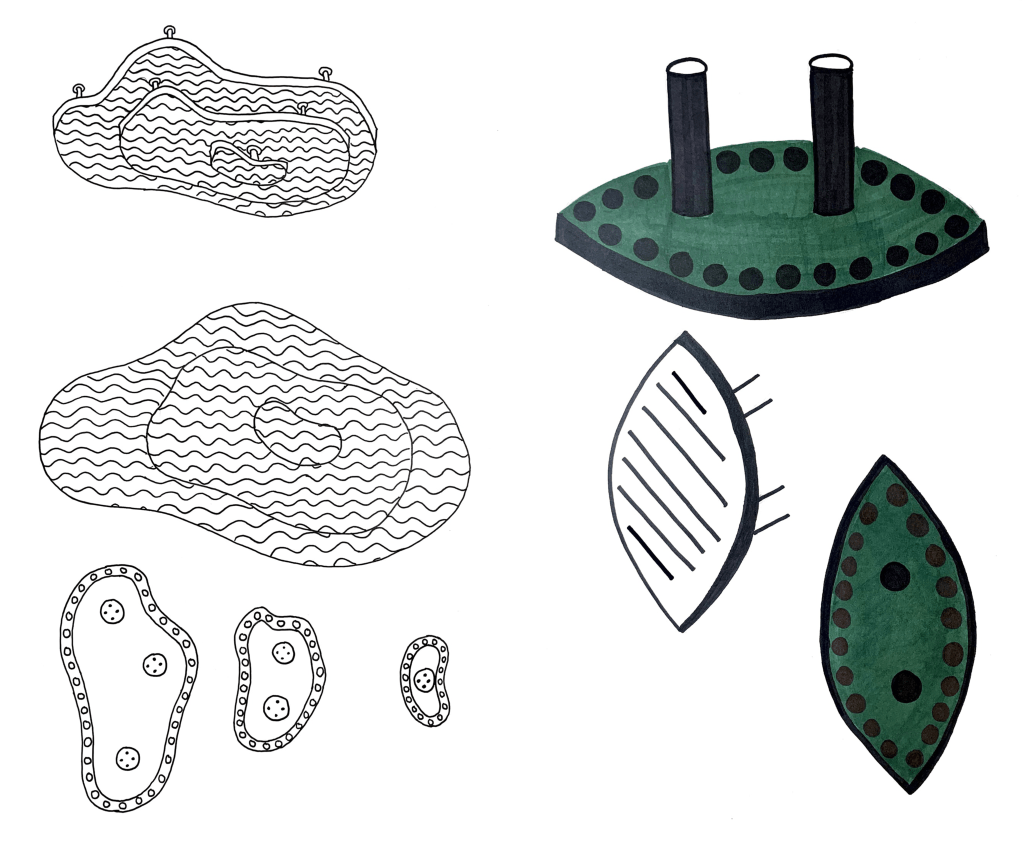

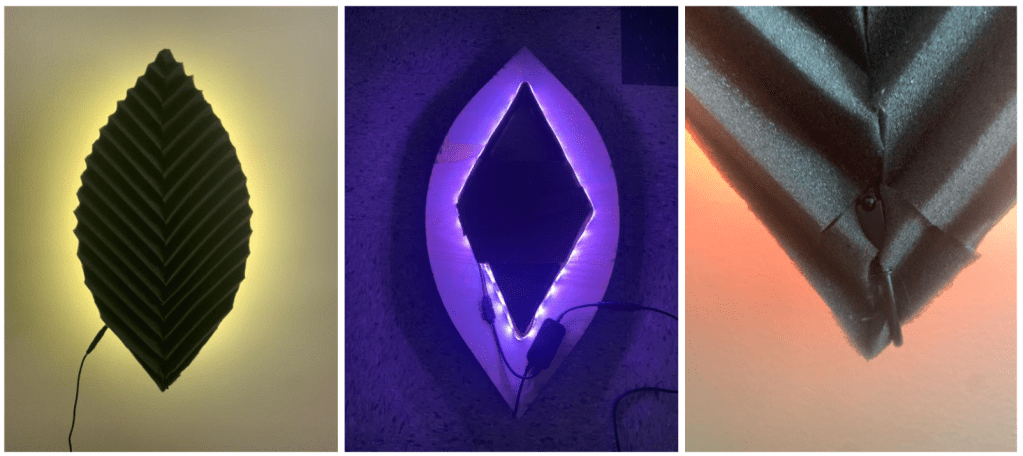

Prototype 1 |

Materials: Cardboard, hot-glue, acoustic foam paneling, LED light strips.

Goal: We made two versions for our first prototype, one with the hexagonal pattern the client asked for, and one mimicking the veins on a leaf. We decided to provide the client with another pattern design because we anticipated they would like a more seamless pattern design. They ended up choosing the leaf vein design over the hexagons.

Outcome: Ability to overdeliver in anticipation of client desires.

Prototype 2 |

Materials: Wood, hot-glue, acoustic foam paneling, LED light strips.

Goal: To incorporate stakeholder feedback into our design and to optimally place the LED sensor.

Outcome: Ability to provide updated prototype in a timely manner for the client (~1-week turnaround).

Final Design |

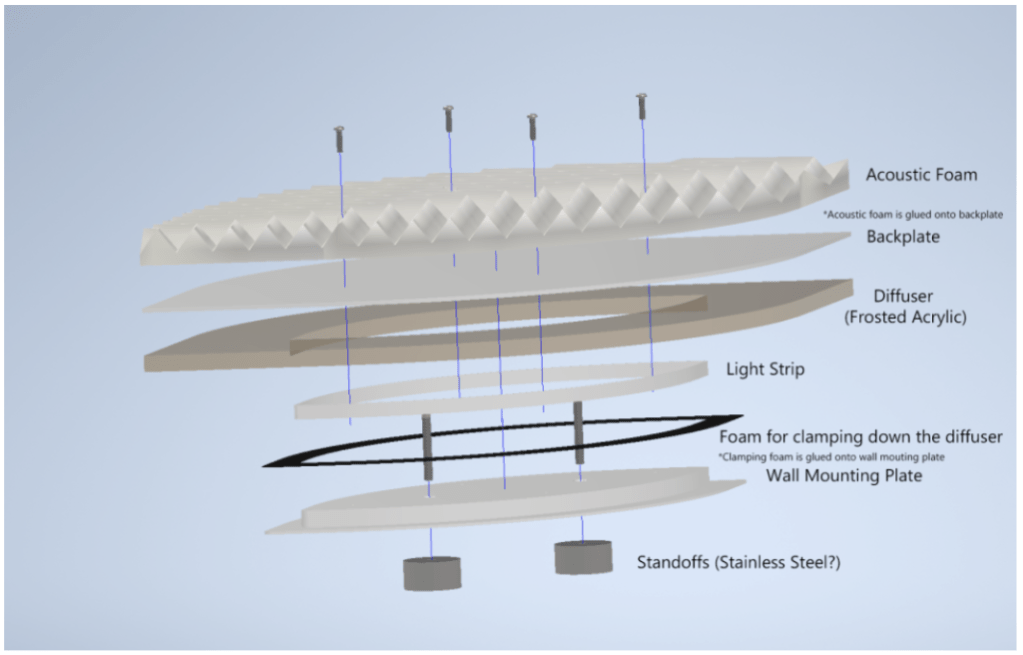

Outcomes: Used Rhinoceros 3D and Unreal Engine to deliver an assembly model and 3D rendering of our final design.